Twin Line Welding Hose: Technical Specifications and Applications

Introduction

Twin line welding hoses are essential components in the welding industry, designed to deliver gases and fluids necessary for various welding processes. These hoses are engineered to provide safety, efficiency, and reliability, ensuring optimal performance in demanding environments.

Technical Specifications

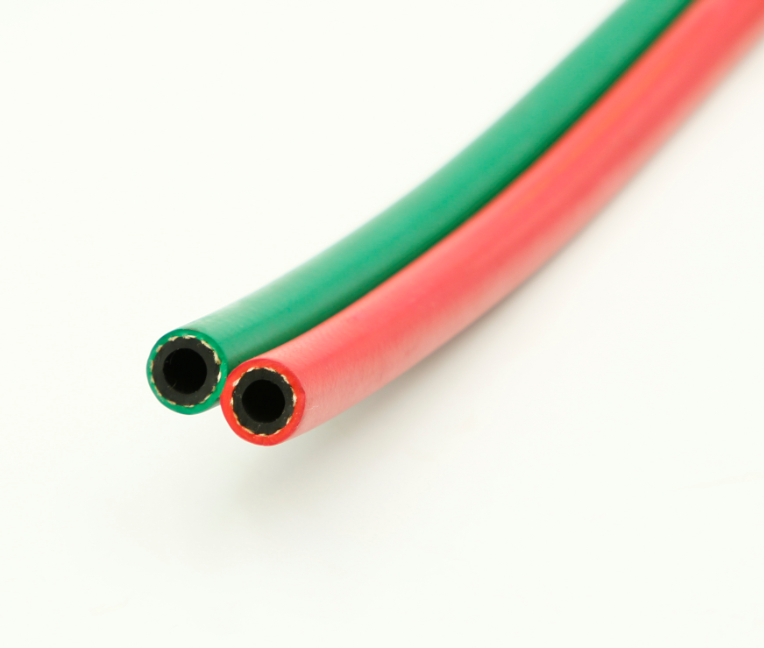

Twin line welding hoses typically consist of two separate tubes, one for fuel gas (such as acetylene) and the other for oxygen. The following are key technical specifications that define the quality and effectiveness of these hoses:

1. Material Composition: Most twin line welding hoses are made from high-quality synthetic rubber or thermoplastic materials that offer excellent flexibility, durability, and resistance to abrasion, chemicals, and UV rays.

2. Pressure Rating: The hoses are designed to withstand high pressures, often rated between 150 to 300 psi (pounds per square inch), ensuring safe operation during welding tasks.

3. Diameter: Standard diameters for twin line welding hoses range from 1/4 inch to 1/2 inch, allowing for varied flow rates depending on the specific welding requirements.

4. Temperature Range: These hoses can typically operate in a wide temperature range, from -40°F to 200°F (-40°C to 93°C), making them suitable for both indoor and outdoor use.

5. Coupling Types: Twin line welding hoses come with various coupling options, including quick disconnects and threaded fittings, which facilitate easy connections to welding equipment.

6. Color Coding: To enhance safety, the hoses are often color-coded—commonly red for acetylene (or other fuel gases) and green for oxygen—allowing for quick identification during use.

Applications

Twin line welding hoses are versatile and find applications in several industries, including:

1. Metal Fabrication: Used extensively in metalworking shops for processes such as cutting, brazing, and welding, twin line hoses provide the necessary gases to ensure high-quality welds.

2. Automotive Repair: In automotive workshops, these hoses are employed for repairs and modifications, allowing technicians to perform welding tasks swiftly and safely.

3. Construction: Construction sites utilize twin line welding hoses for on-site welding applications, ensuring durability and reliability under varying environmental conditions.

4. Shipbuilding: In shipyards, these hoses are crucial for welding and cutting operations on large metal structures, requiring hoses that can withstand harsh marine conditions.

5. Artistic Welding: Artists and sculptors often use twin line welding hoses for creating metal sculptures, benefiting from the precision and control these hoses provide.

Conclusion

Twin line welding hoses are an indispensable tool in the welding industry, providing safe and efficient delivery of gases essential for various welding processes. Their robust technical specifications and wide range of applications make them a preferred choice for professionals in metal fabrication, automotive repair, construction, shipbuilding, and artistic endeavors.