Defining Hydraulic Hose Standards

Depending on where you are, there are several different national and international hydraulic hose standards with varying measurements, tolerances, and parameters.

For example, the European Norm/Standard (EN) and the International Standards Organization (ISO) both set their hydraulic hose standards, which differ from each other.

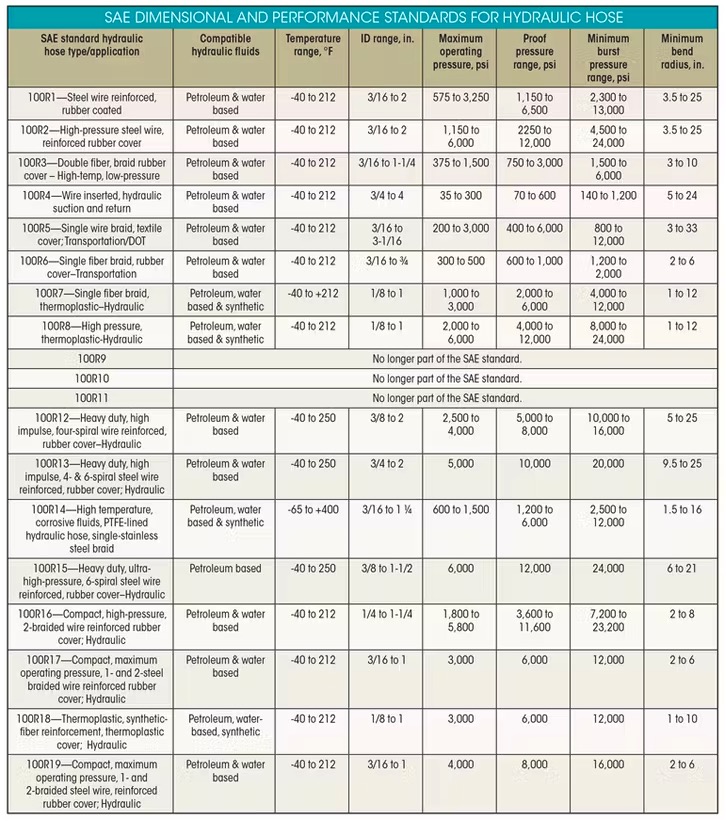

In North America, the typical hydraulic hose standards are set by the Society of Automotive Engineers or SAE. This organization provides a series of hydraulic hose standards in the 100R series, defined under SAE Standard J517.

The 100R series hydraulic hose standards differentiate the hoses based on their construction and ideal usage conditions, including temperature, pressure, and fluid type. Before we get into the specifics of each hose, let’s take a moment to go over the different parts of a hydraulic hose

Hydraulic Hose Construction

While the specific parameters of every hose are different, they generally define three key aspects of the hose: the tube, the strengthening or reinforcement, and the outer, protective cover.

Tube

The tube that runs along the inside of a hydraulic hose is responsible for actually transporting hydraulic fluid. For that reason, it has to be able to withstand constant contact with hydraulic fluid, including both biodegradable and petroleum-based fluids.

Because the hose is the part that comes into contact with the fluid, it also needs to withstand other factors, including extremes in temperature, corrosion, and tension.

Reinforcement

While the tube is the part that houses hydraulic fluid, the reinforcement is there to strengthen the line, protecting it from any spikes in pressure that may occur. The higher the pressure in the tube, the more support you’ll want to prevent it from bursting or leaking.

Hydraulic hoses come with either textile or steel reinforcement. Textile reinforcement is a woven fabric designed for low-pressure usages, while steel reinforced hoses have either a braided cover around the hose or individual courses of wire wrapped around the tube.

Wire wraps always come in even-numbered layers, with each successive layer wrapped in the opposite direction of the previous layer.

Cover

The protective outer layer is known as the cover, and this is the first layer of protection from exterior damage. Usually made from synthetic rubber or textile braiding, the cover helps prevent abrasion and corrosion damage and can provide insulation to prevent the tube from being damaged by external heat, cold, or UV damage.