Oxygen Hose: Technical Specifications and Applications

Introduction

Oxygen hoses are essential components in various industries, particularly in medical, industrial, and welding applications. These hoses are designed to transport oxygen safely and efficiently, ensuring that the gas maintains its purity and integrity during use. This article will delve into the technical specifications of oxygen hoses and their applications across different fields.

Technical Specifications

1. Material Composition:

– Oxygen hoses are typically made from high-quality materials such as rubber, PVC, or thermoplastic elastomers. These materials are chosen for their resistance to ozone, UV light, and high temperatures, which are crucial for maintaining the hose’s durability and functionality.

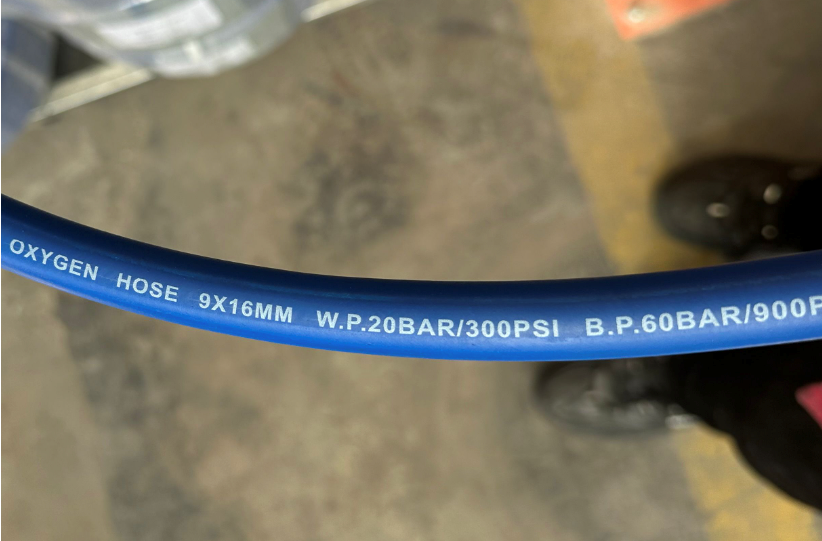

2. Pressure Rating:

– Oxygen hoses are designed to withstand high pressures, usually ranging from 150 PSI (pounds per square inch) to 300 PSI. The specific pressure rating will depend on the hose’s diameter and wall thickness, ensuring safe operation under various conditions.

3. Temperature Range:

– The operating temperature for oxygen hoses generally spans from -20°F to 150°F (-29°C to 65°C). This wide temperature range allows for versatility in different environments, from outdoor applications to controlled indoor settings.

4. Inner Diameter (ID):

– Oxygen hoses come in various inner diameters, typically ranging from 1/4 inch to 1 inch. The choice of diameter affects the flow rate of oxygen, with larger diameters allowing for higher flow rates suitable for industrial applications.

5. Length:

– Oxygen hoses are available in multiple lengths, often ranging from 25 feet to 100 feet. Custom lengths can also be manufactured to meet specific customer requirements.

6. Fittings and Couplings:

– Oxygen hoses are equipped with specialized fittings and couplings that ensure a secure connection to oxygen tanks and delivery systems. These fittings are often made from brass or stainless steel to prevent corrosion and maintain the integrity of the oxygen supply.

Applications

1. Medical Use:

– In the healthcare sector, oxygen hoses are used to deliver oxygen to patients requiring respiratory support. These hoses connect oxygen concentrators or tanks to masks or nasal cannulas, ensuring a continuous supply of medical-grade oxygen.

2. Welding and Cutting:

– Oxygen hoses are integral to welding and cutting operations, where they supply oxygen to fuel gases like acetylene. This combination is crucial for creating high-temperature flames needed for metalworking.

3. Industrial Applications:

– In various industrial settings, oxygen hoses are used for processes such as oxidation and combustion. They play a vital role in enhancing efficiency and safety in manufacturing operations.

4. Aquaculture:

– Oxygen hoses are also utilized in aquaculture to aerate water in fish tanks and ponds. This ensures that aquatic life receives adequate oxygen levels, promoting healthy growth and survival rates.

5. Firefighting:

– Firefighters use oxygen hoses to provide breathable air in hazardous environments. These hoses connect to portable oxygen tanks, enabling firefighters to operate effectively in smoke-filled areas.

Conclusion

Oxygen hoses are indispensable tools across multiple industries, offering safe and efficient transportation of oxygen. Their technical specifications, including material composition, pressure ratings, and temperature ranges, make them suitable for various applications, from medical to industrial uses. Understanding these parameters is crucial for selecting the right hose for specific needs, ensuring safety and effectiveness in operations.