Water Discharge Hose: Technical Specifications and Applications

Water discharge hoses are essential components in a variety of industrial, agricultural, and municipal applications. Designed to transport water efficiently, these hoses are engineered to withstand the rigors of demanding environments. This article will delve into the technical specifications and applications of water discharge hoses, highlighting their importance in various sectors.

Technical Specifications

1. Material Composition:

Water discharge hoses are typically made from durable materials such as PVC, rubber, or polyurethane. PVC hoses are lightweight and resistant to abrasion, while rubber hoses offer superior flexibility and temperature resistance.

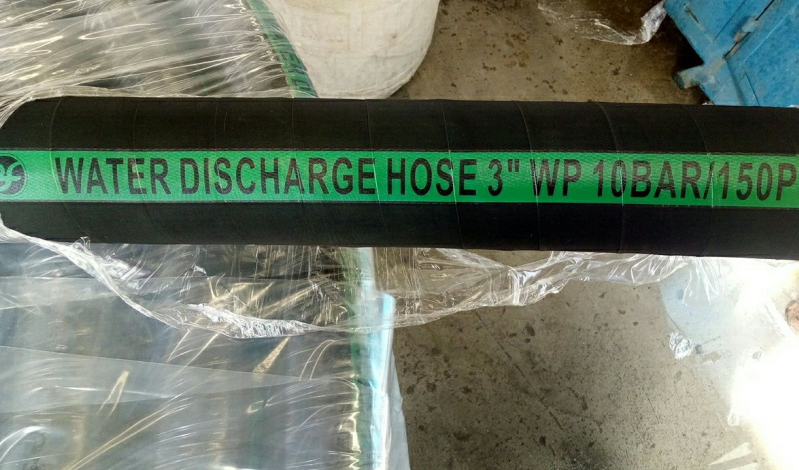

2. Diameter:

Common diameters for water discharge hoses range from 1 inch to 12 inches, with larger diameters available for specific industrial applications. The choice of diameter affects the flow rate and pressure capabilities of the hose.

3. Pressure Rating:

Water discharge hoses are rated for different pressure capacities, generally ranging from 50 PSI to 150 PSI. Higher pressure ratings are essential for applications that require the hose to handle significant water pressure without bursting.

4. Temperature Resistance:

Depending on the material, water discharge hoses can typically withstand temperatures ranging from -20°F to 180°F. This temperature range is crucial for applications that involve hot water or exposure to extreme weather conditions.

5. Length:

Water discharge hoses are available in various lengths, often ranging from 50 feet to 200 feet. Custom lengths can also be manufactured to meet specific project requirements.

6. Reinforcement:

Many water discharge hoses feature internal reinforcement, such as spiral wire or textile braiding, which enhances their strength and flexibility. This reinforcement is vital for preventing kinking and ensuring longevity during use.

Applications

Water discharge hoses are versatile and find applications across several sectors:

1. Agriculture: In farming, these hoses are used for irrigation systems, allowing for efficient water transfer from pumps to fields. Their ability to handle varying pressure levels makes them ideal for different irrigation techniques.

2. Construction: During construction projects, water discharge hoses are utilized for dewatering applications. They help remove excess water from excavation sites, ensuring a dry and safe working environment.

3. Municipal Services: Water discharge hoses are critical in municipal water management, including flood control and drainage systems. They facilitate the rapid movement of water during heavy rainfall or flooding events.

4. Industrial Use: In industrial settings, these hoses are employed in processes that require the transfer of large volumes of water, such as cooling systems and various manufacturing processes.

5. Firefighting: Some water discharge hoses are specifically designed for firefighting applications, providing reliable water flow to extinguish fires. Their durable construction ensures they can withstand harsh conditions.

Conclusion

Water discharge hoses are integral to numerous applications requiring efficient water movement. With their robust technical specifications, including material composition, pressure ratings, and temperature resistance, they are tailored to meet the demands of various industries. Understanding these parameters is crucial for selecting the right hose for specific applications, ensuring optimal performance and durability.