Chemical hoses are hoses specifically designed to transport hazardous chemicals, liquids, and gases. They are made from a variety of materials and come in different sizes and lengths. Chemical hoses are used for a variety of applications in industries such as oil & gas, chemical processing, pharmaceuticals, food & beverage, and many more. They provide safe and reliable transportation of hazardous materials while protecting the environment from contamination.

TYPES

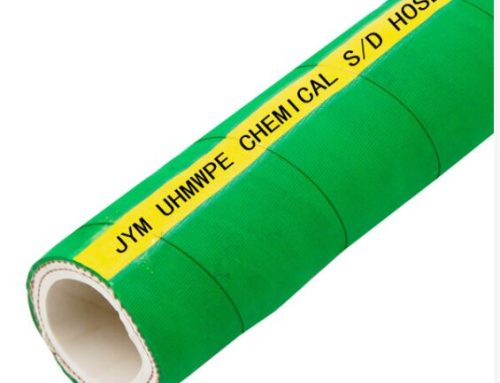

- UHMWPE CHEMICAL HOSE

UHMWPE chemical hoses are an essential tool for industries that require the safe and secure transfer of chemicals. They are made from ultra-high molecular weight polyethylene (UHMWPE) which makes them highly resistant to wear and tear, as well as chemical corrosion. UHMWPE chemical hoses are also lightweight and flexible, making them easy to transport and install in any environment. The unique properties of these hoses make them ideal for use in a variety of industrial applications such as transferring acids, solvents, and other hazardous materials.

- XLPE CHEMICAL HOSE

XLPE Chemical Hose is a type of hose used for transferring chemicals and other abrasive materials. It is designed to handle a wide range of corrosive chemicals, solvents, and petroleum products. This type of hose is made from cross-linked polyethylene, which provides superior chemical resistance and flexibility. The hose also features an abrasion-resistant cover for added protection against wear and tear. XLPE Chemical Hose is ideal for use in industrial applications where chemical transfer needs to be done safely and efficiently.

SIZES

When it comes to selecting the right hose for a chemical application, size is an important factor. Chemical hoses come in a variety of sizes, allowing for flexibility in terms of pressure and flow rate. It is important to select the right size hose to ensure that the chemicals are being transported safely and efficiently.The size of a chemical hose will depend on its intended use, as well as the type of material it is made from.

When it comes to choosing the right chemical hose for your needs, size matters. Different sizes of chemical hoses are designed for different applications and pressures, so it is important to choose the right size for your specific needs.

The size of a chemical hose is greatly dependent on the material used to make it. Different materials have different properties, which can affect the size of the hose. By understanding how these materials affect the size of the chemical hose, manufacturers can better select and use them for their products.

Chemical hose making materials can have a major impact on the size of the hoses they are used to make. Different materials can affect the size of hoses in different ways, such as increasing or decreasing their diameter, wall thickness, and overall length. For example, some materials may be able to expand when heated up which could result in larger hoses. On the other hand, some materials may shrink when cooled down which could result in smaller hoses. A thorough understanding of these effects is essential for ensuring that manufacturers produce quality products with consistent sizes.

TEMPERATURE RATING

When handling hazardous materials, it is important to pay close attention to the temperature rating of the chemical hose. Temperature ratings are a key factor in determining the safety and efficiency of a chemical hose when handling hazardous materials. It is important to know what temperature range your chemical hose can handle in order to prevent any accidents or damage from occurring.

Temperature ratings are an important factor to consider when selecting a chemical hose. The temperature rating of a chemical hose determines the operating temperature range of the hose in order to ensure safe and reliable operation. It is important to select the right chemical hose with a suitable temperature rating for your application.

CHEMICAL SUCTION AND DELIVERY HOSE

Chemical suction and delivery hoses are an essential part of any industrial process. They provide a safe, reliable, and cost-effective way to transport chemicals from one point to another. With the right chemical suction and delivery hose, companies can ensure that their operations are running smoothly and efficiently. Additionally, these hoses can be used for other applications such as transferring liquefied gases, hazardous materials, water treatment chemicals, and more. By investing in a quality chemical suction and delivery hose, businesses can make sure that their operations are running smoothly while also protecting their workers from any potential hazards.

Chemical suction and delivery hoses are essential pieces of equipment for a wide range of industries. From the transportation of hazardous chemicals to the safe delivery of food and beverage products, these hoses play a critical role in ensuring that processes run smoothly. With advancements in materials and technology, chemical suction and delivery hoses have become increasingly reliable, efficient, and durable.

WHAT IS CHEMICAL HOSE USED FOR?

Chemical hoses are specialized hoses designed to transport hazardous chemicals, and other materials safely and securely. They are an essential component of any chemical manufacturing or processing facility, as they provide a safe and reliable way to move hazardous materials from one place to another. Chemical hoses come in a variety of shapes, sizes, and materials, so it is important to choose the right hose for the job.

Chemical hoses are a type of hose used to transport hazardous and corrosive chemicals from one place to another. They are specially designed with materials that can withstand the harsh chemicals and provide safety for those handling it. Chemical hoses have a wide range of use cases, such as transferring acids, solvents, fuels, and other hazardous materials in industrial settings. They are also used in agricultural applications to transfer fertilizers and other chemicals for crop production.

WHAT YOU SHOULD CONSIDER WHEN SELECTING A CHEMICAL HOSE

When it comes to selecting a chemical hose, there are several factors you should consider. From the type of material used to the pressure rating, temperature range and size of the hose, each factor must be carefully evaluated to ensure you get a hose that is suited for your application. In addition, the selection of a chemical hose should also take into account its compatibility with other components in your system as well as its durability and flexibility. With these considerations in mind, you can make an informed decision when selecting a chemical hose for your needs.